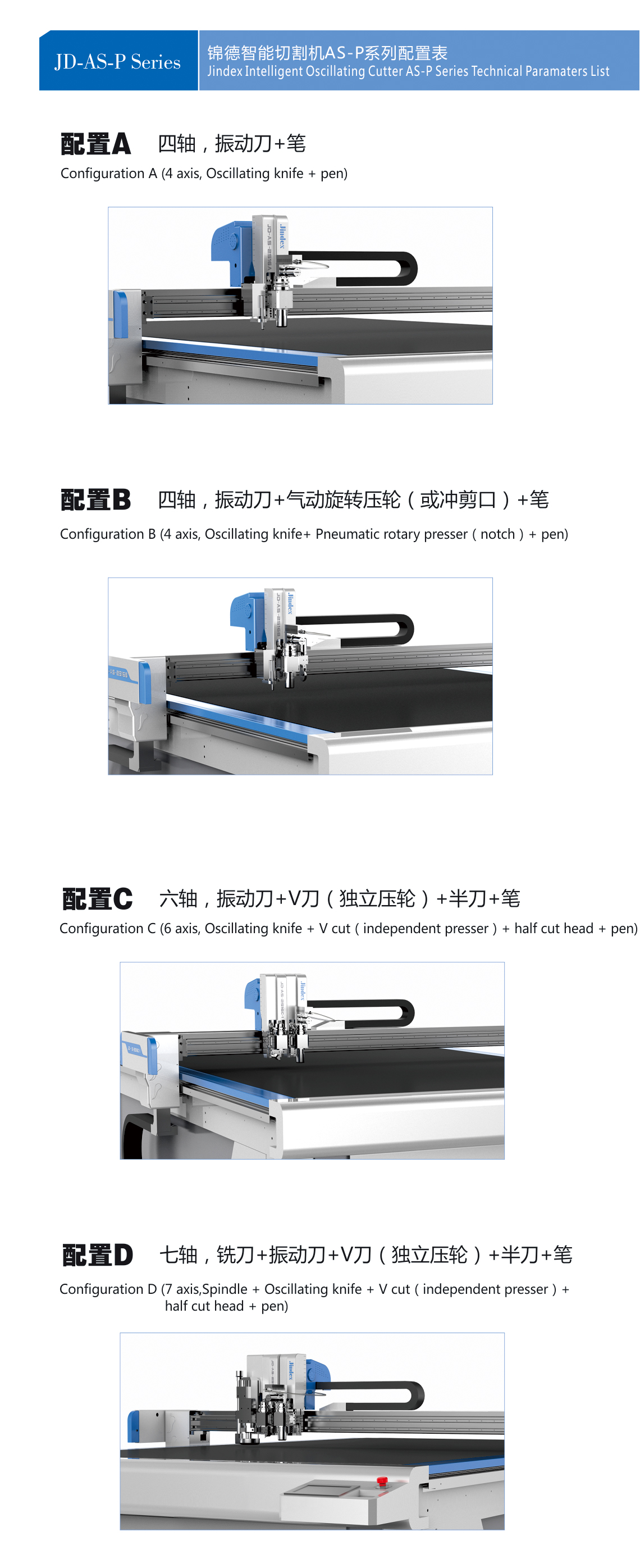

功能特點

Functions and special feature

◇ 電(diàn)動式震(zhèn)動刀槍頭,力量強勁(jìn),震動頻率高,每分鍾可達25000次。

Electric shock and head, strength, vibration frequency is high, up to 25000 times per minute.

◇ 切割機傳動係統采用進口齒輪、齒條(tiáo),切割精度完全達到往返原點零誤差。

Cutting machine transmission system adopts imported gear, rack, cutting precision to achieve zero error.

◇ 采用日本三菱伺服(fú)電機,可由電腦隨意控製振動刀和壓輪的(de)下刀深度(dù)。

Using Servo-motor from Mitsubishi, With computerized control.

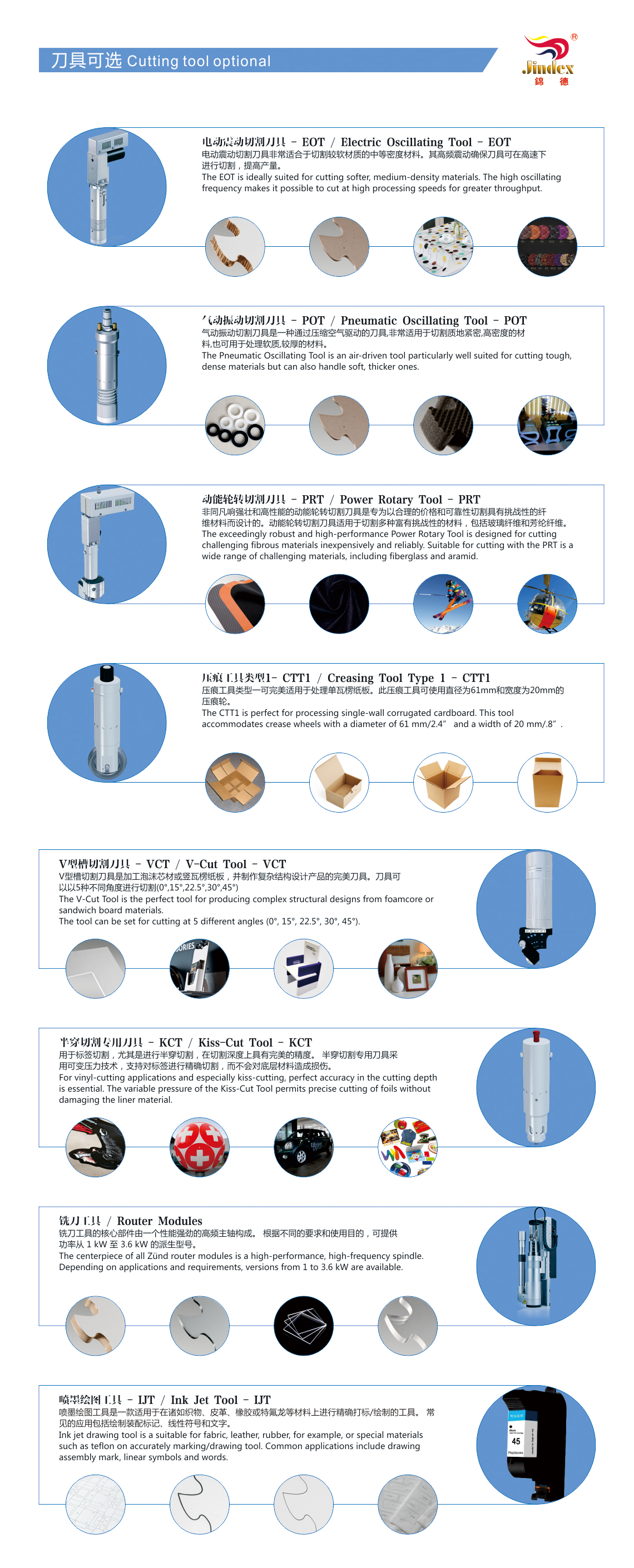

◇ 配置振動刀、拖(tuō)刀,筆畫工具以及可選配置半刀,銑刀,開槽刀,圓(yuán)刀(dāo)、壓痕刀等多種刀具(jù),可實現寫字畫線、虛(xū)線裁切、半斷裁切、全(quán)斷裁切、銑刀裁切、多種材料V-CUT開槽、開銑槽、大小壓輪壓痕(hén)、硬質材料刮痕等實用功能。

The configuration of vibration knife, drag knife strokes, tools and optional half knife, cutter, slotted knife, knife, cutter, indentation knife and other tools, can achieve the office of line drawing, cutting, cutting, dotted half cut off all the cutting and milling cutter cutting, various materials, V-CUT slot milling, pressing wheel, indentation size the utility function and so on scratch hard materials.

◇ 全自動攝像(xiàng)定(dìng)位功能:自動實現(xiàn)印刷材料的定位切割,無需手(shǒu)動定位即可切割出外形輪廓。

Fully automatic camera positioning function: automatic positioning and cutting of printed materials, without manual positioning can be cut out the outline.

◇ 采用先進成熟的滾動式台麵設(shè)計,平台寬幅可訂(dìng)製大小,理(lǐ)論裁切長度無限(xiàn)製,采用(yòng)真空吸風設計,超勁風、強吸力(小樣片吸附不再困難)。

The type of rolling table design advanced, platform width can be customized size, no limit theory of cutting length, by vacuum suction design, super wind, strong suction (sample sheet is no longer difficult).

◇ 采(cǎi)用完全自主研發的上位(wèi)機控製係統,即學即會的人性化操控界麵,支持遠程教(jiāo)學,遠程維護,遠程升級,讓客戶使用更省心。

The completely independent research and development of computer control system, namely the humanized operation interface, support for remote teaching, remote maintenance, remote upgrade, let the customer with more peace of mind.

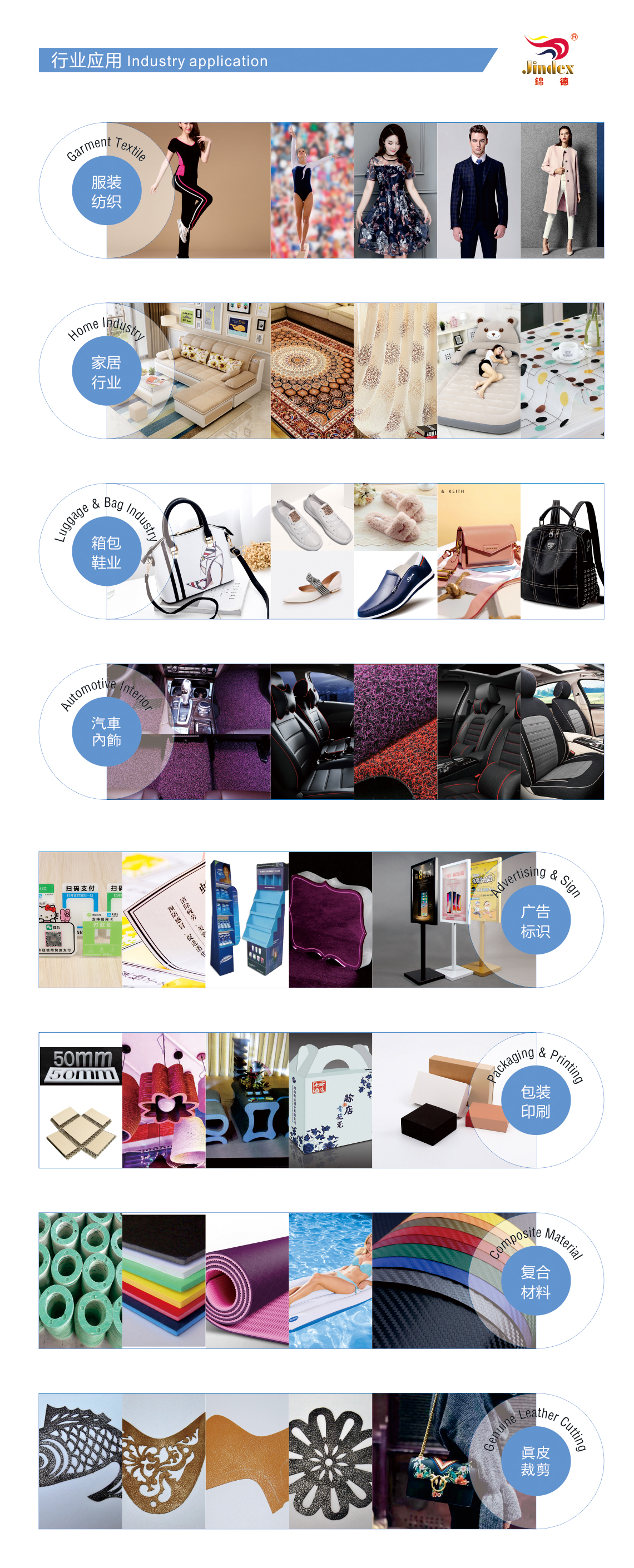

◇ 可連接任意CAD軟件,廣泛應用於廣告印刷(shuā)行業、製鞋行業、服飾行業、複合材料、箱包行業、汽車行業、電子行業、裝飾行業、家具等行業之繪圖(tú)與切(qiē)割。

Any CAD software can be connected. It is widely used for plotting and cutting for the industries and sectors like garment, shoe making, cases, handbags, laser cutter molds plotting, lighting fixtures, advertising gifts, self-adhesive and color box packing.

◇ 可選裝料架及自動送料裝置。

Optional charging rack and automatic feeding device.

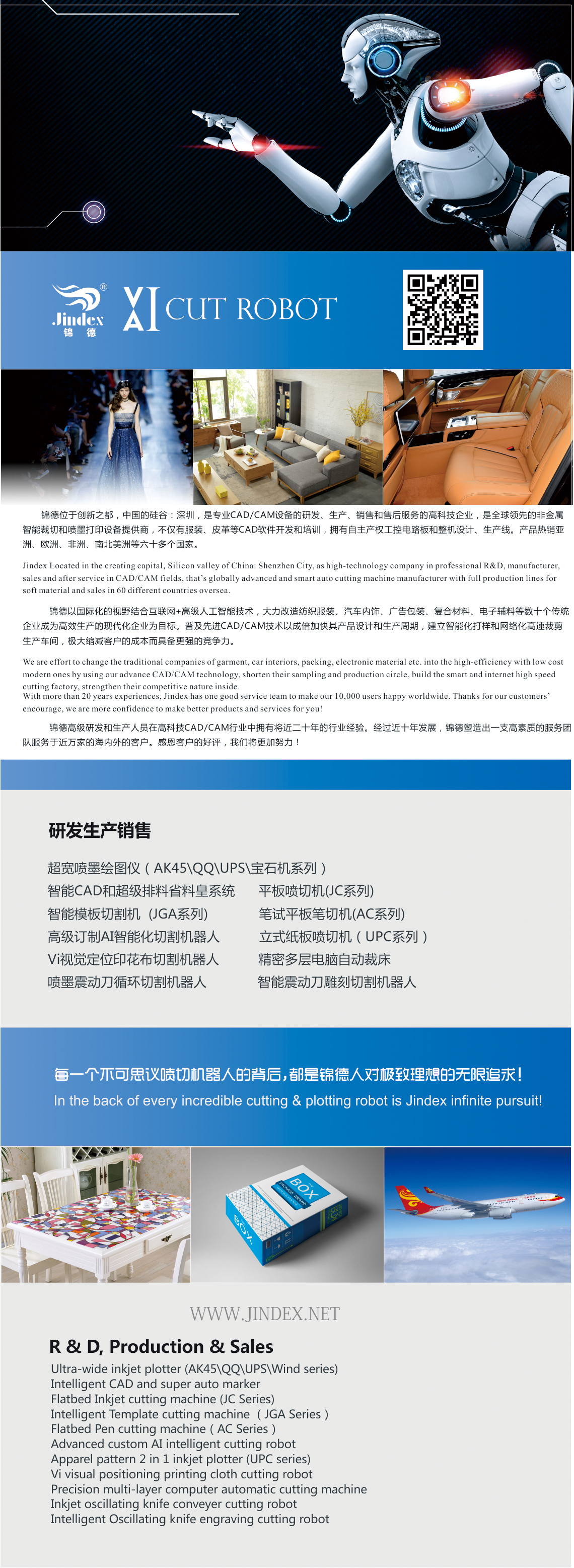

| 電(diàn)腦數控振動刀切割機 JD-AS-C係列技術參數標(biāo)準表 | |||

技術參數/型號 | JD-AS-1410C | JD-AS-1813C | JD-AS-2516C |

工作特性 | 電腦(nǎo)操作與(yǔ)切割機同時進(jìn)行,快速完成數據傳輸,可連續使用 | ||

切割速度 | 最快可達1500mm/s | ||

切割厚度 | 0.2-30mm | ||

切割(gē)材料 | 可切(qiē)割30mm以下的蜂窩紙板、瓦楞紙、塑料瓦(wǎ)楞板、灰板紙、白卡紙、膠片、複合材料、皮料(liào)、布(bù)料、膠板、珍珠棉(mián)和(hé)泡沫KT板等多(duō)種材料。 | ||

筆數 | 8組不同的筆(bǐ)畫(huà):半刀、全(quán)刀、壓輪設置(zhì)、V刀、衝剪口 | ||

定位(wèi)方式 | 紅外線激光燈 | ||

固定(dìng)紙的方式 | 真空吸附和氣(qì)壓機(jī)械固定 | ||

切割精度 | ±0.2mm | ||

重複精度 | ≦0.05mm | ||

切割圓形(xíng)直(zhí)徑 | ≧5mm diameter | ||

傳輸接口 | 以太網口 | ||

兼容軟件(jiàn)格式 | AI軟件、Autocad、Coreldraw等軟(ruǎn)件都可以直接輸出,無需轉換,且帶自動優化 | ||

指令係統 | HP-GL和GP-GL | ||

數控麵板 | 液晶顯示和觸點按鍵 | ||

傳動(dòng)材(cái)料(liào) | 高精度模組的一級傳動機構 | ||

工作電壓和功率 | 交流220V 380V ±10%,50HZ;整機功(gōng)率6kw;保險絲規格(gé)6A | ||

電機類型 | 伺服電機 | ||

振動刀頭 | 振動刀頭(tóu)電機每分鍾25000轉 電動和(hé)氣動刀頭可選 | ||

切割麵積 | 1400mm*1000mm | 1800mm*1300mm | 2500mm*1600mm |

外觀尺寸 | 2160*1680*1220mm | 2570*1990*1200mm | 3300*2250*1200mm |